Insulating Concrete Forms (ICF) Swimming Pools: Getting the Most Splash for Your Cash

Insulating Concrete Forms are frequently used for many structures around homes and commercial buildings. BuildBlock customers have constructed retaining walls, fences and gates, fire pits and more. We’ve had an increase in request for information around ICF swimming pools. ICFs in swimming pools not only speed up construction, but the insulating foam prevents more than 80% of the heat loss of the pool from energy transfer to the ground. This means it’s much cheaper to heat your pool, but also extends the length of the pool season.

“ICFs have been used from swimming pools since the very beginning of the industry.”

ICF Builder Magazine

In the past few years several manufacturers have created additional coatings and finishes specifically for ICFs that work well in pool environments too. BuildCrete Stucco, a Gigacrete product, is perfectly suited as the waterproof coating and plaster directly applied to the EPS foam. Another full line of ICF pool construction products can be found at sider-crete.com

The greatest cost savings, though, are long-term. “Experts calculate that up to 80% of a pool’s heat is lost through the sides and bottom of the pool, due to the fact that the ground conducts heat far more efficiently than air does. Considering the surface areas involved, continuous insulation is the best choice.”

ICF Builder Magazine

ICF pools are being built on many types of projects. Usually found in large custom homes, they are also found in community pools and as an energy efficient addition to existing homes as well.

ICFs primary component is EPS foam. They are easily formed into almost any shape imagined and since they form an extremely flat and smooth wall, they are easily finished to a consistent flat surface. The EPS on the inside, along with the uniform straight corners and joints work great with PVC membranes as an alternative interior finish. Companies offer a 10-year waterproof warranty when a PVC membrane is installed by a certified professional.

Why ICF

Most residential swimming pools are built in conjunction with high-end custom homes, and frequently, when the owners choose to build with ICFs for longevity and reduced energy costs, they’ll choose an ICF pool for the same reason.

ICF Pool Advantages

- Faster Construction

- Modular, Light-weight, Easy to use.

- Easily Stacked.

- BuildRadius provides easy construction of curved ICF walls without extra unnecessary cutting and bracing.

- Environmentally Friendly, Low Waste

- Easy Rebar Placement

- More consistent wall finish

- Allows for standard pre-mix concrete and trucks

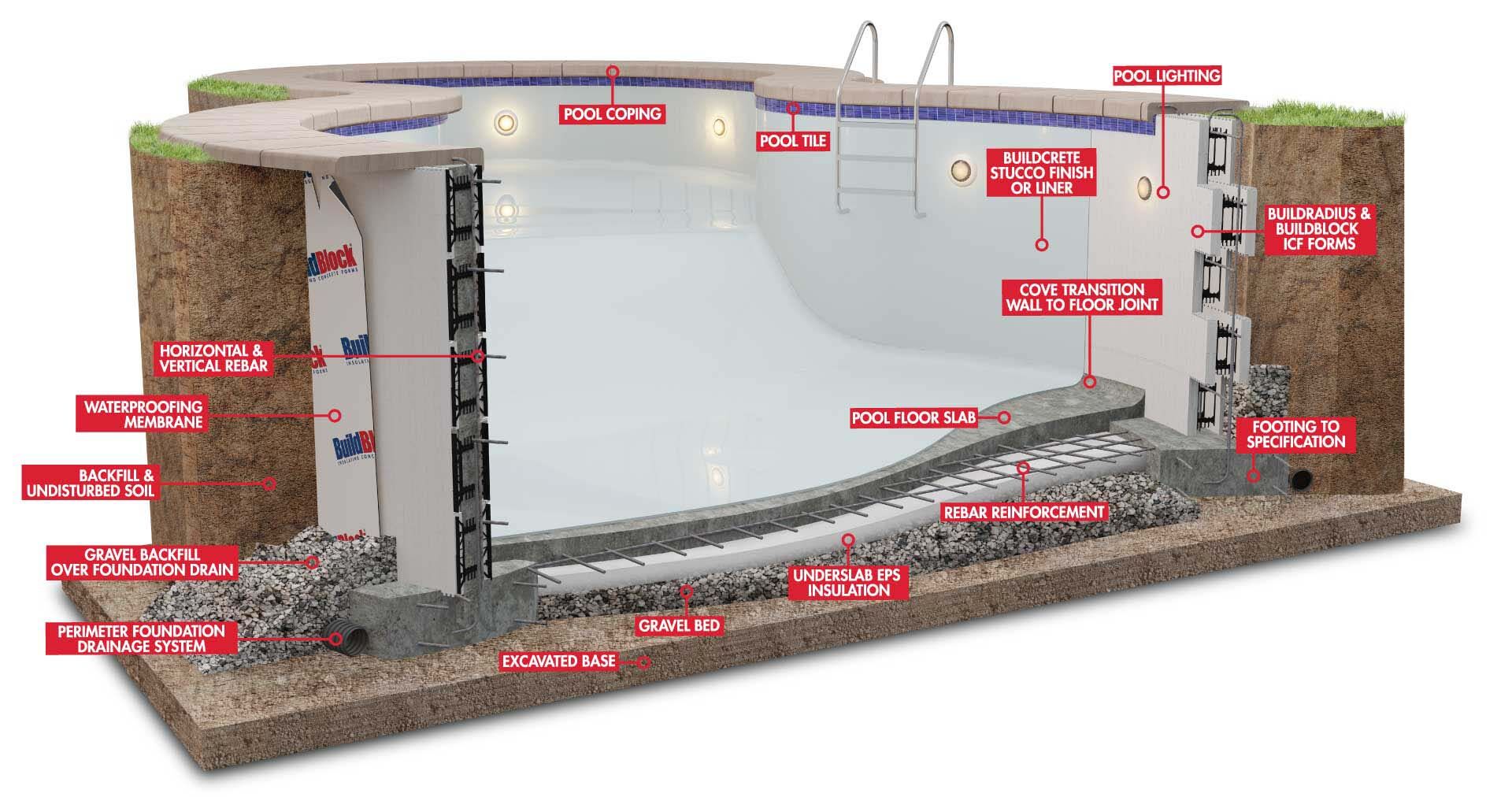

ICF Pool Construction

Pool construction is similar to standard ICF wall construction.

- Excavate the pool area and footings.

- After excavation, footings are poured and the ICF walls are stacked.

- Plumbing lines are installed per design and Steel reinforcement and bracing is added per the engineer’s specifications and the ICF walls are poured.

- The pool bottom is filled and leveled with a smooth, non-compacting fill such as sand or fine gravel.

- A moisture barrier is installed beneath the foam.

- Under-floor insulation is added. Typically 4” cut foam, but BuildDeck could also be used for thicker insulation.

- Steel rebar is added as reinforcement to specification.

- The slab floor is poured. If the pool has a slope to a different depth, typically the two horizontal slabs are poured then the slope is poured so they meet evenly. The whole slab should be poured at one time.

- A cove transition piece is installed to create a smooth wall to floor transition.

- Finishing the pool is possible in several ways.

- BuildBlock recommends finishing directly on the ICF with BuildCrete Stucco, a GigaCrete product, at least 3/8” thick with an embedded fiberglass mesh. The advantage of the BuildCrete process is that it’s a one-coat finishing process.

- The stucco product can be finished completely smooth and is 100% waterproof.

- It can be pre-colored or painted.

- Also recommended is the Sider-Plast System by Sider-Crete. sider-crete.com/product-specs-icf-coatings/ The pool is then finished with the Sider-Proof Top Coat.

- Another coating option that can be used both horizontally and vertically is Perma-Crete.

- BaseCrete offers a waterproofing basecoat that any traditional pool plaster can be applied to.

- BuildBlock recommends finishing directly on the ICF with BuildCrete Stucco, a GigaCrete product, at least 3/8” thick with an embedded fiberglass mesh. The advantage of the BuildCrete process is that it’s a one-coat finishing process.

- If desired, a vinyl pool liner can be used as the final layer. They typically last 8-10 years. It is still recommended to finish the ICF with BuildCrete or similar first.

- Form-A-Drain or similar system is installed along with a peel and stick waterproofing like PolyWall Homestretch to the outside of the ICF and gravel is backfilled to the waterproofing. The drainage system needs to either drain to daylight, a sump, or other location to keep the two water tables separate. Water infiltration from the exterior of the pool can leach into the pool’s interior layer of EPS foam, allowing the freeze and thaw cycles or saturation to break the bond between foam and plaster.

- The pool interior is finished with tile and pool coping or decking is placed and the rest of the pool is finished normally.

ICF pools will bring the homeowner energy savings and lower maintenance for the life of the pool. It speeds up construction and offers lots of design flexibility. Contact BuildBlock for more information about building your ICF pool today!

BuildBlock Offers ICF Pool Kits!

Make building a pool easy with a pool kit from BuildBlock. With multiple designs available, you can find the pool of your dreams and get started on your backyard osasis today!

Find the perfect design at icf-pools.com!

Related Posts

Construction Starts for the First Home of Nicor Gas’ “Smart Neighborhood” Using BuildBlock ICFs

Aurora, IL, July 10, 2025— Kicking off a groundbreaking step toward sustainable housing, Nicor Gas and Habitat for Humanity have officially begun construction on Habitat Green Freedom—an ambitious initiative utilizing BuildBlock Insulating Concrete Forms (ICF) to build disaster-resilient, net-zero homes that redefine affordable living.The first house project is located at…

Wall Parging for ICF Construction: What It Is, Why It’s Needed, and How to Do It Right

If you're working with Insulated Concrete Forms (ICFs), one question always comes up: how do you finish that exposed foam between the ground and your siding? The answer is wall parging—a critical step that not only protects your build but also enhances its curb appeal.

Built to Withstand: How ICFs Play a Critical Role in Fire Resilient Construction

In 2023, Oklahoma City faced a devastating wildfire season, with 97 recorded blazes destroying 76 structures and winds reaching 50-60 MPH. Amidst this destruction, one home stood resilient: BuildBlock Founder Mike Garrett’s ICF (Insulated Concrete Form) home.