Form-A-Drain

FORM-A-DRAIN® is the 3-in-1 foundation solution that forms footings, provides an integrated drainage system, and can be easily adapted to vent radon where needed. Designed for residential basement appl

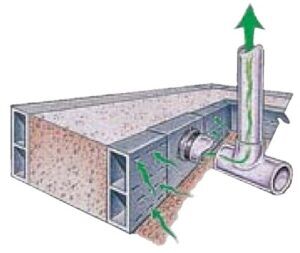

ications, Form-A-Drain consists of lineal sections installed as the foundation footing forms. Unlike standard wood forms, Form-A-Drain lineals stay in place permanently after completion of the concrete pour and because they form a complete sub-slab perimeter loop around the foundation, Form-A-Drain functions as a foundation drainage and a radon collection system as well. Since it stays in place, Form-A-Drain also shaves valuable time from the construction schedule; there’s no need for a crew to return the next day to remove, strip, clean and transport forms to the next jobsite.

The 6”, 8”, & 10” Form-A-Drain system exceeds all applicable code requirements for foundation drainage systems and meets those code requirements in superior fashion to HDPE corrugated pipe.

Form-A-Drain is a dual footing form that creates parallel dedicated drainage pathways tight to both sidewalls of the footing. This unique arrangement of large, connected drainage pathways ensures that water is channeled around the building perimeter at the optimal height relative to footings and slabs (the configuration of Form-A-Drain lineals ensures that the bottom of the drain path is at least 6” below the bottom of the basement slab); in practice, HDPE corrugated pipe is seldom installed at a consistent height relative to footings. Furthermore, corrugated pipe is often installed in discontinuous sections that may not be visible at the time of inspection. Because Form-A-Drain is installed prior to footing pour, the entire continuous system is fully visible at the time of footing inspection.

Form-A-Drain is available with lateral components that connect the lineals to daylight (where the site configuration will permit such) or the sump pit required by IRC 405. This same section does not require a dedicated interior footing drain pathway, only a porous layer of sand or gravel with a provision for mechanical discharge – i.e. the sump pit and pump. Form-A-Drain exceeds this code requirement by creating a dedicated pathway tight to the footing, channeling water at exactly the position where it can be the most effective – at the outside perimeter of the basement slab.

An Evolution in Footing Construction, Drainage, & Radon Evacuation

We highly recommend and use Form-A-Drain®for sub-surface water drainage in the construction of all basements. Take a moment to view this section and you’ll see why we believe Form-A-Drain is the best product available for this very important aspect of basement construction.

Form-a-Drain forms precise foundation footings, with an ideally located foundation drainage system above the bottom of the footing and below the foundation wall. The system allows for simple adaptation to function as an effective means for radon reduction since it forms a complete loop around the foundation.

Installing FORM-A-DRAIN® is simple using lineals, couplings, and corners which ensure a precise form setup.The entire system is left permanently in place, eliminating the need to return to strip, remove, clean, and transport forms to the next jobsite.

What is Form-A-Drain and How Does It Work?

- Form-A-Drain® is a complete, permanently installed system that forms footings, drains foundations, and provides a sub-slab perimeter radon reduction system. CertainTeed designed and developed FORM-A-DRAIN, a patented combination footing form system, foundation drainage system, and radon reduction system for residential basement applications.

- The system consists of lineal sections installed as the foundation footing forms. Upon completion of the concrete pour, the system stays permanently in place and performs the function of a foundation drainage system.

- It is also an effective method of reducing radon since it is a sub-slab perimeter system that forms a complete loop around the foundation.

- FORM-A-DRAIN is the subject of BOCA Research Report #95-37, renewed annually.

Homeowner Features & Benefits

Features | Homebuilder Benefits |

|---|---|

Ideally located drainage system, parallel to the footing, below foundation wall | Relieves hydrostatic pressure on walls and slabs, reducing the risk of cracking |

Drainage system cannot sag or crimp | Reduces risk of blockage or uneven drainage |

Greater water intake capacity than traditional drain pipe, 50% more water inlet area than minimum ASTM standards | Ensures rapid collection of groundwater; minimizes the possibility of water infiltration |

Level installation | Uniform drainage of the foundation, easier to set wall forms |

Smooth interior wall | Allows for the free flow of water and less chance of build-up and clogging |

Drainage is provided for both the inside and outside of foundation footing build-up and clogging | Better drainage protection against water infiltration; reduces the risk of cracking and leaking |

Strong, rigid PVC construction; greater stiffness | Minimizes the possibility of system failure due to a collapsed or crushed drainage system |

Conforms with EPA’s “ Model Standards & Techniques for Radon Control in New Residential Buildings” and ASTM E 1465-92 Standard Guide for Radon Control Options | Acceptance by local code officials and inspectors |

Contractor Features & Benefits

Features | Contractor Benefits |

|---|---|

Stay-In-Place lineal footing form system | Eliminates wood or metal form cost and form removal, cleaning, and transportation costs |

Less elapsed time between footing pour and wall construction | Reduces carrying cost expense |

Immediate drainage capability | Can minimize downtime in inclement weather |

Simple adaptation with a round pipe “T” and vertical PVC pipe stack provides radon reduction | Eliminates material and labor costs for separate |

Eliminates the need for conventional corrugated poly drain tile | Reduces material and labor associated with drain tile installation |

Complete line of lineals, couplings, 90° and 45° corners, vertical T’s & L’s, outlets, and accessory items | Can accommodate virtually any foundation layout |

No oiling of forms required | Reduced oil cost and elimination of oil handling and disposal |

Dry fit joints allow for job site assembly without the use of solvent cement or mechanical fasteners | Reduced form set-up time |

Easy to cut with hand or power saw | No additional or special tools required for cutting; fast installation |

Spacer straps available in pre-determined width dimensions | Improved set-up time by reducing the time used for measuring |

System Components

Form-A-Drain lineals are manufactured from PVC (polyvinyl chloride) material using a high content of recycled materials, in convenient 12-foot lengths. Three full dimensional sizes are available: 4″, 6″ and 8″ – all sizes are 2-1/4″ wide. Each 12-foot lineal weighs less than 6 pounds in 4″, less than 8 pounds in 6″, and less than 11 pounds in 8″, for ease of transportation, handling, and joining. Accessories are available, including couplings, corners, drainage outlets, T’s, and vertical angle pieces. Grade stakes can be left in place; they do not have to be pulled. Spacer straps are available in various widths to ensure proper footing width. All fittings and accessory items are made to precise CertainTeed product specifications. Fittings are manufactured for easy assembly without mechanical or solvent fastening. Lineals can be cut easily with a hand or power saw to exact lengths required.

Let Us Help

Contact BuildBlock today and let our staff answer your questions and help make your project a success.